Panmaker will oversee the sales of Mira shells across the European continent.

To place an order, please provide your information using the form below. Once you’ve done so, kindly notify us, and we will proceed to process the data to create the invoice.

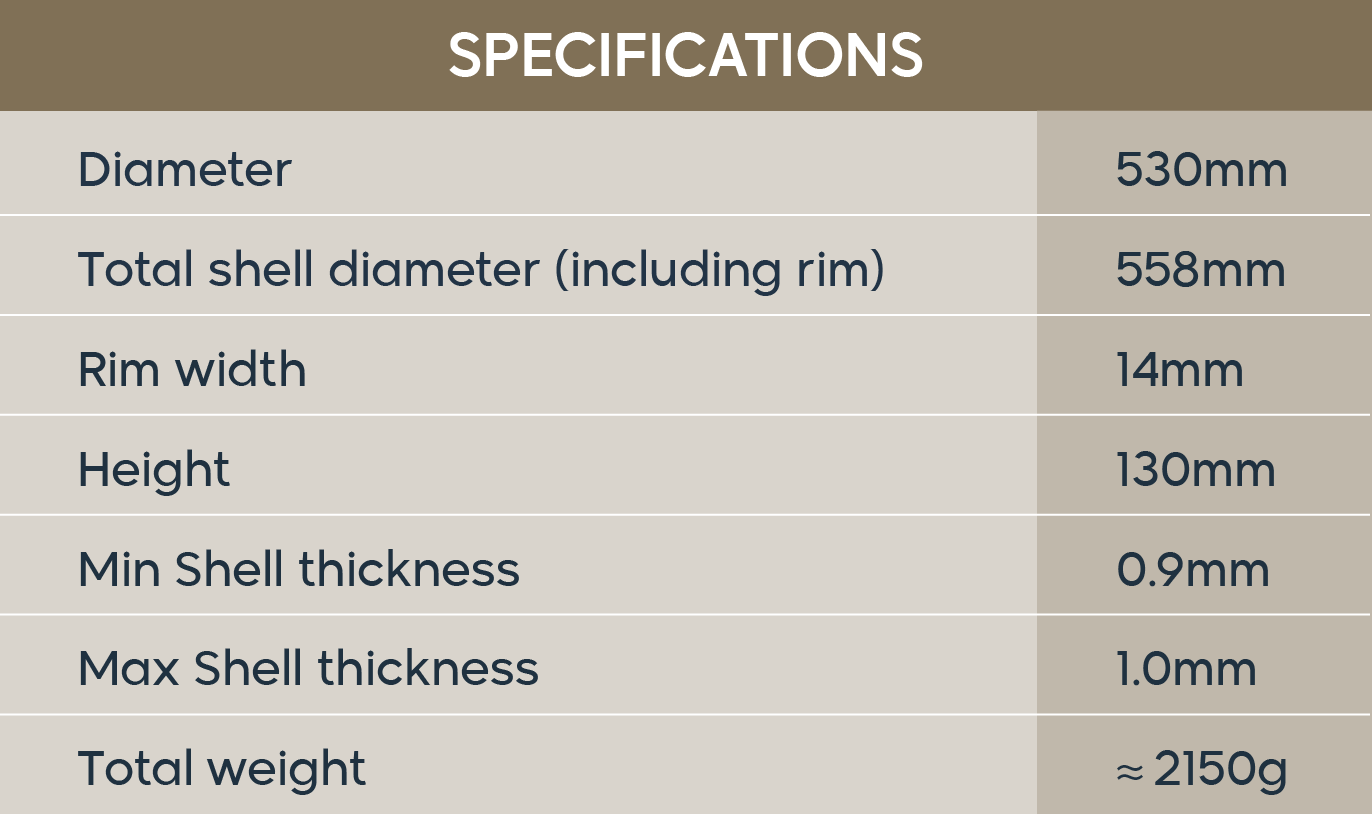

Currently, three types of shells, AISI 430, AISI 439 and AISI 441 are available. All variants come in 1mm thickness, featuring a diameter of 530mm and a depth of 130mm. Their shells also fit our shaping ring.

Mira shells will be sold per box of 8 – 11. Shipping costs are the same, regardless of the amount of shells, so we recommend 11 at a time.

Price per shell:

AISI 430: €65

AISI 439: €70

AISI 441: €70

Starting from this point onward, all the text has been authored by Mudra, with whom we have collaborated on establishing this partnership over the past few months.

We’ve tested a lot of different steel compositions and sinking methods during the last 5 years, each one with its own upsides and downsides. This led us to develop a material we are finally 100% satisfied with.

We are happy to give the Handpan makers more choices and new timbres to explore.

Our Shells compared to other sinking methods:

- Better thickness distribution;

- You don’t spend time sourcing the material and forming the shell, your work is focussed on building;

- The shell geometry and thickness is almost identical from one shell to the other, so there is less room for unwanted surprises;

- No risk of big chemical variations if you source the material on your own. If we take AISI 430 for example, the possible chrome variation is 50%, this is a huge difference for Handpan Makers.

Our Shells compared to other Deep Drawn available on the market:

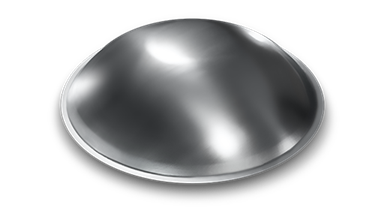

Shell curvature – The central area was specifically designed to be easy to work with. Making the area flat for the ding is an easy task on our Shells even for low dings and mutant dings;

Aesthetics – The scratches located near the rim are almost unnoticeable. It’s possible to completely remove them with a soft polishing;

Protective film – Every shell comes with a protective film stuck to it. This provides more protection during shipping, avoiding possible scratches. Depending on your building style, you can make the dimples and shape with the film, so it saves time cleaning the shell before annealing;

Distribuition – The thickness distribution is more equal throughout the shell, the difference between the thicker and thinner part is smaller than 10%;

Composition – We work with a very specific and controlled chemical composition and in our opinion, it provides greater stability, tonal quality and oxidation resistance. Besides, one batch doesn’t change much from the other;

Stability – The overall thickness is greater than other Deep Drawn Shells we’ve tested, and it’s around 100g heavier. In our opinion, this increases stability and gives a more ceramic timbre. However, it doesn’t limit the scale options. It’s still possible to make instruments with many notes as you can see on our videos;

Method – Our Deep Draw method is different from the slow hydraulic press usually used.

We provide top shells only that can also be used as bottom shells. We believe the shape and tune of the Gu hole is part of the maker’s creation and uniqueness.

AISI 430

Stainless Steel AISI 430 1 mm: This is the most common Stainless Steel Grade. It has a very long sustain, bright and warm sound, pronounced attack and looks shinier than the others. Lamination lines are more visible on this material. It feels harder to work with compared to the other materials.

AISI 439

Stainless Steel AISI 439 1 mm: If you are looking for a sound in between Stainless Steel and Nitrided Steel, this is the best option for you. It has the ceramic and percussive quality of Nitrided Steel, combined with the long sustain of the Stainless Steel. The volume perception of this material is slightly lower than AISI 430. Its surface is rougher than AISI 430, and there are no lamination lines. This material is softer to work with, so shaping and tuning need to be well done in order to have a good stability on this material.

AISI 441

Stainless Steel AISI 441 1 mm: This steel alloy has remarkable versatility and unique properties. Compared to the AISI 430 and 439, it offers the longest sustain, with the ability to adjust sustain duration by heating at different temperatures. Renowned for its deep and warm sound, with round shoulder tones. Its tonal qualities generally diverge from traditional metallic characteristics. It’s the easiest material to tune and stabilize. It has a matte finish, similar to the AISI 439.”